SummaryI designed this scribe set to practice turning and 4th-axis machining of smaller components, skills that were necessary for future projects, such as the H-1 Liquid Rocket Engine.

The scribes use a wide variety of materials with different geometries, to increase the complexity and skill set required to complete manufacturing.

|

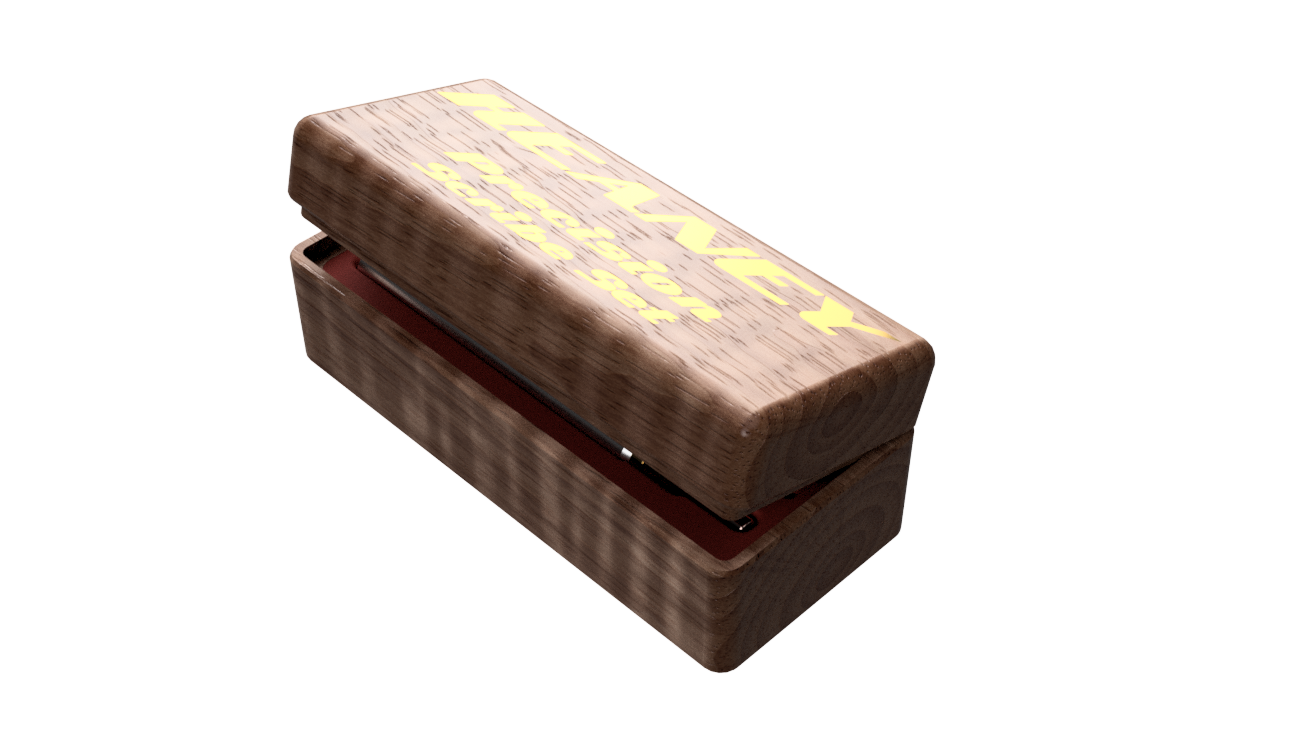

Display BoxThe scribes can be displayed in their storage box. It is lined with custom cut foam that keeps the scribes in their place, and has two recessed brass plates in the foam that can be engraved with pictures or text.

The box itself is machined from two pieces of mahogany, which are joined with brass hinges at the back. The top of the box has inlaid brass letters cut from 0.40" brass plate.

|

Scribe Mk. 1

The first scribe is the simpler of the two. It is comprised of an aluminum body, a brass and copper reducing sections, and a carbide tip. It is slightly larger than a sharpie pen.

Assembly of the metal pieces is done with a high-temperature Loctite. The Carbide tip is retained with a low-temperature Loctite, so that it can be heated and removed in the event of damage.

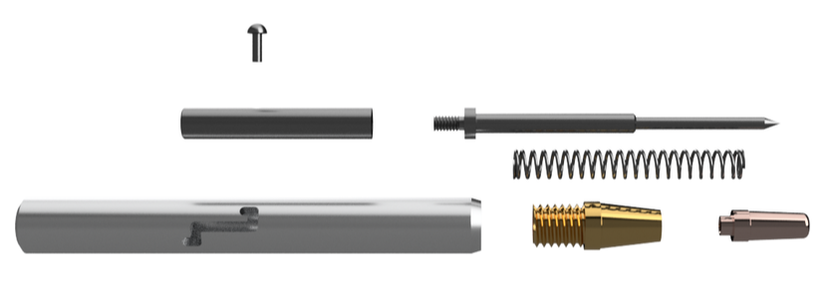

Scribe Mk. 2The second scribe is more complex than the first, and uses a retracting tip. The tip is extended and retracted using a spring and a small bolt near the top of the scribe.

The body of the scribe is made of aluminum, brass, and copper. The brass and copper are held together with Loctite. The brass is screwed into the aluminum body, so that the replaceable tip can be accessed.

The carbide tip is secured into a replaceable steel cartridge with Loctite. The replaceable cartridge is screwed into the actuating core of the scribe. The core of the scribe can be actuated with the bolt, which is connected with Loctite, and is constrained by a slot in the aluminum. The entire system is actuated with a spring.

|

|

Additional Information

The drawings for the Mk. 1 and Mk. 2 scribe can be found below.

|

| ||||||||||||